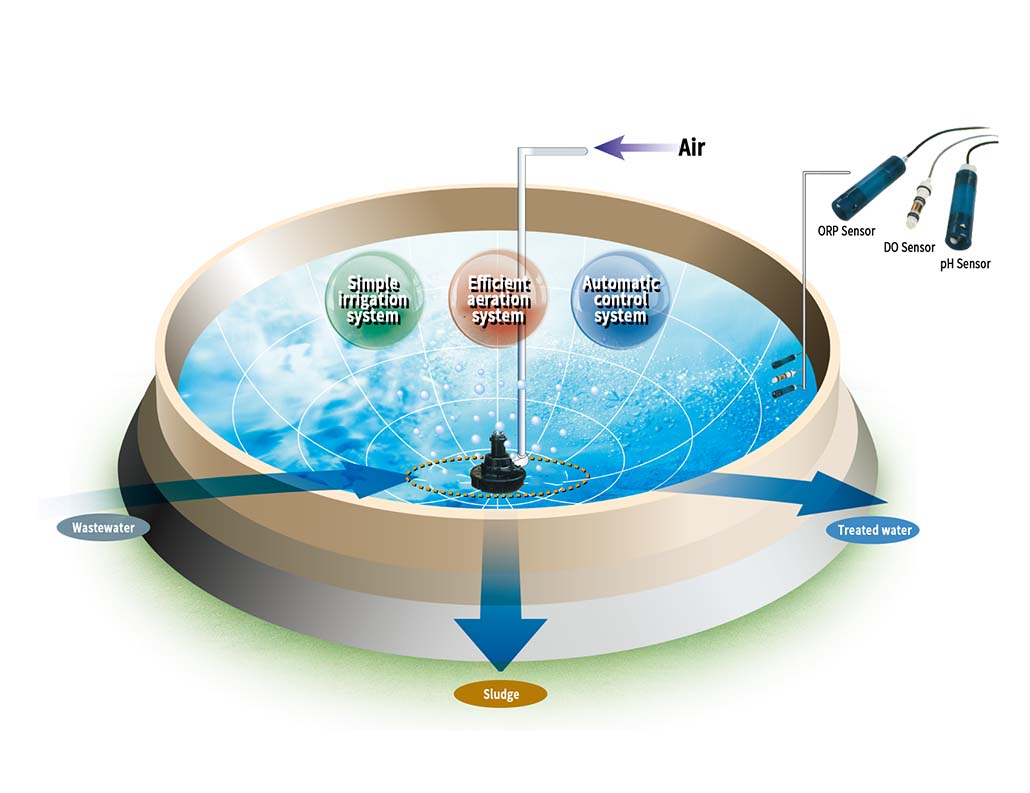

Complex Lagoon System® with low load design / batch type activated sludge treatment method

Features

-

POINT 1

Single processing reaction tank

The composite lagoon is a single processing reaction tank acting as a settling / aeration tank.

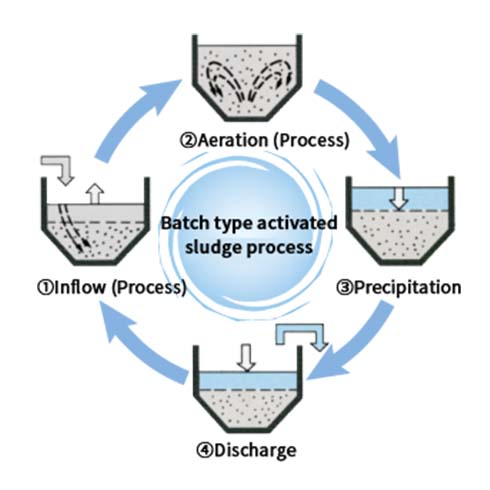

The four steps [raw water inflow], [decomposition by aeration of BOD etc.], [treated water separation by activated sludge sedimentation], and [treated water discharge] are repeated endlessly.

It is called a batch activated sludge treatment method.

-

POINT 2

No need for dilution water

It is designed to process without dilution, even with high-concentration water.

It is not necessary to secure a large amount of well water for dilution. -

POINT 3

Flexible performance

The amount and concentration of wastewater is constantly changing, depending on the season and management conditions.

but the aeration and settling times can be easily changed, allowing flexible operation in response to changes in the raw water.

However, the aeration and settling times can be easily changed, allowing for flexible operation in response to changes in the raw water. -

POINT 4

Efficient aeration system

Our unique-shaped reaction tank and the aeration system reduces the cost with efficient aeration. The conventional system requires about 1.7 kwh to introduce 1 kg of oxygen, while this system consumes 0.9 to 1.3 kwh for the same activated sludge treatment method

-

POINT 5

Low running cost

Easy adjustment of operation of the equipment enables optimization of the power consumption. Maintenance costs can also be kept low due to less mechanical breakdown and wear-out.

-

POINT 6

Extremely simplified equipmentst

Anyone can easily manage the operation because there are few management processes. Since the quality of activated sludge is stable, it is also easy to dehydrate excess sludge.

Functions

It highly removes, without dilution, BOD and SS of high-concentration organic wastewater (BOD~30,000ppm) , and is also excellent in denitrification (nitrogen removal) and biological phosphorus removal.

Especially it excels in denitrification, and it complies with the provisional livestock standards of the country of nitrate nitrogen from July 2019.

In addition, we also support advanced treatment of phosphorus etc. by chemical injection as needed.

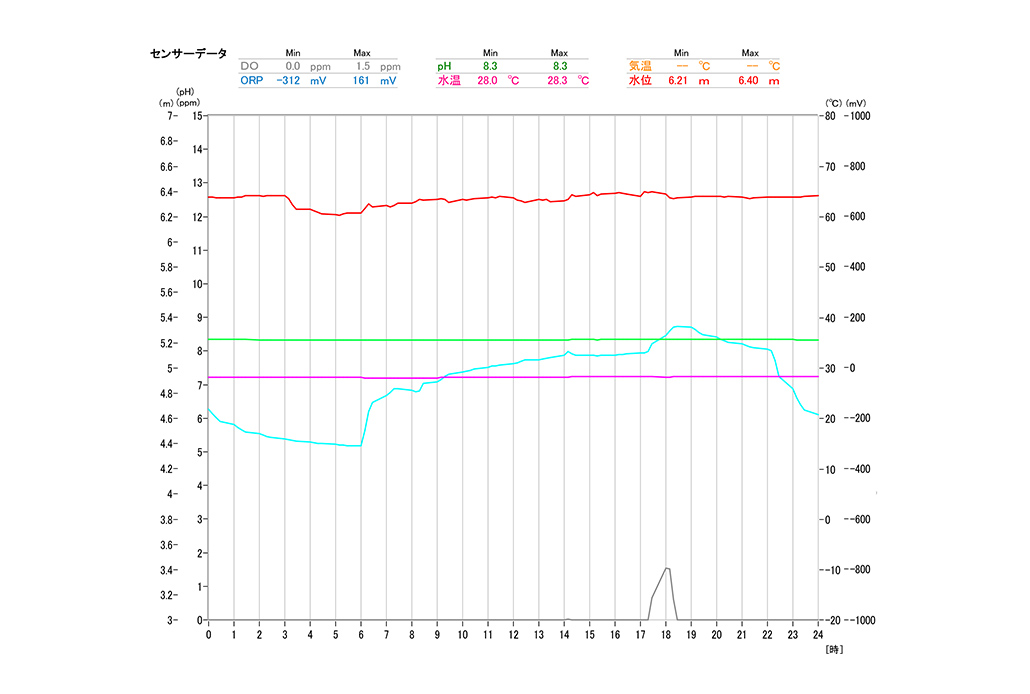

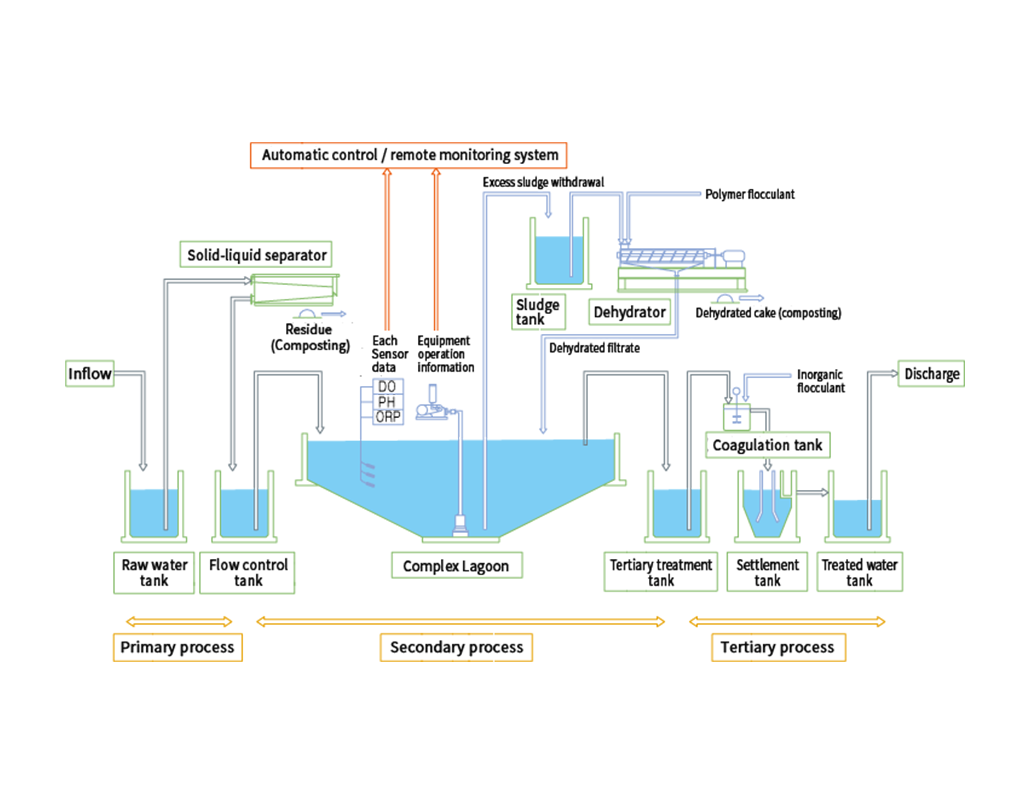

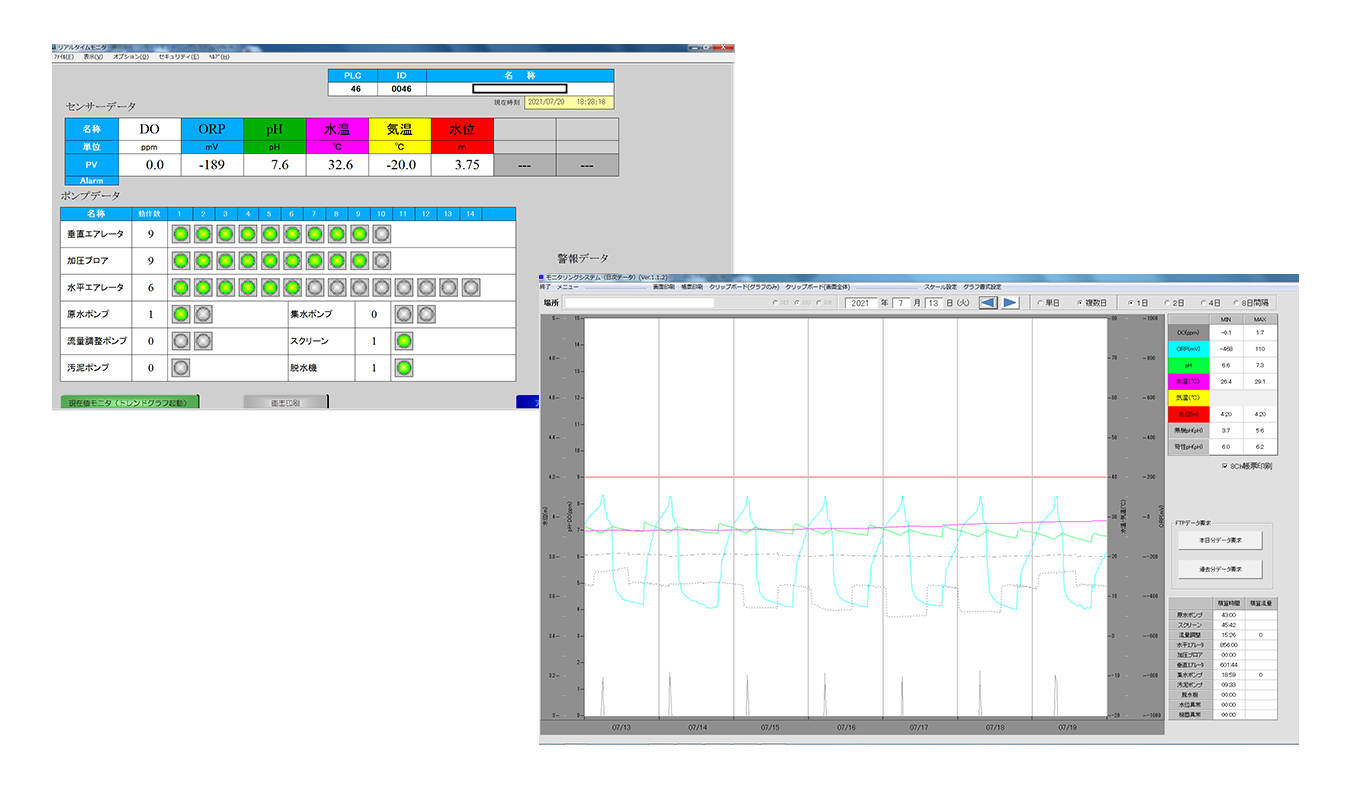

Measurement / automatic operation control

Various sensors are permanently installed in the reaction tank.

Sensor data is recorded on the graph along with the machine operation.

By checking this data, the operators can easily manage aeration output, then keep stable treatment quality of wastewater.

Remote monitoring system

We monitor the data of each farm and help you manage the operation of the site in real time. We also send alert e-mail to the administrator about the error of water level or failure of each tank.

Excess sludge treatment

It is a standard to treat the sludge with a dehydrator of low power, small parts, corrosion resistance, and less cleaning water.

Purifying flow

-

STEP 1

Remove coarse dust (about 0.5 mm or more) with a screen and store the sewage in the flow control tank.

-

STEP 2

The sewage is regularly poured into the lagoon and aeration starts. When oxygen is supplied, bacteria eat the nutrients (BOD, nitrogen) contained in the sewage and decompose it into carbon dioxide and water / nitrogen gas.

This is the basic principle of purification. -

STEP 3

When the aeration is fully completed, the equipment will stop. Bacteria sink to the bottom of the lagoon, and good supernatant water with low BOD and nitrogen appears on the surface of the lagoon.

-

STEP 4

A cycle completes by discharging the supernatant fluid.

The system automatically and endlessly repeats 1-3 cycles per day.

Bacteria above a certain level (excess sludge) is removed and the water is separated using a dewatering machine.

The filtrate is returned to the lagoon and the dewatered cake is usually returned to the field to be fermented and composted in a composting facility.

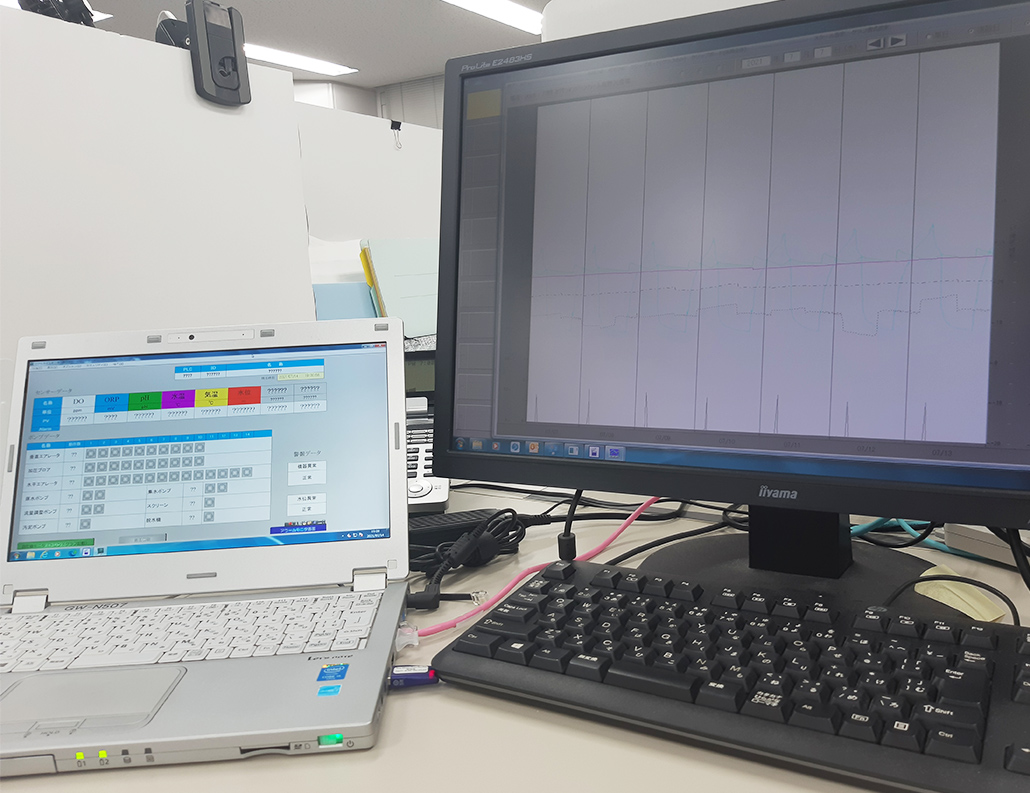

Automatic control / remote monitoring system

-

-

By setting the operation time and combining it with the water level conditions and sensor values of each tank, the facility will be operated fully automatically.

The operation program can be changed according to the usage environment.

The data of sensors installed in the lagoon and various machine operations are automatically recorded.

Utilizing these records for operation adjustment, we grasp the purification function and feed it back to operation management.

The operation will be by far secure than relying on experience and intuition.

We monitor the recorded data remotely with mobile line. We grasp the processing status from the data and give operational advice if necessary.

It is also able to receive alarms by e-mail, such as water level abnormalities that occur when the water level in the treatment tank reaches the upper limit, and equipment abnormalities that occur when the machine does not operate due to a malfunction.

Inquiries about water treatment business, products, and services

Contact information for water treatment business