Screen and dehydrator

Screen

It removes solids of about 0.5 mm or larger in raw water.

We propose from among various models by comparing the solids concentration of the liquid, required treatment capacity, price, and ease of maintenance.

Dehydrator

This machine is used to dewater excess sludge liquid (a mixture of bacteria and water) and, if necessary, to separate fine solids from raw water.

The quality of the treated water varies greatly depending on the capacity.

We select a model from our lineup, ranging from large capacity to small size, easy handling, robustness, simplicity of parts, required washing water volume and power, according to the properties and volume of the liquid to be treated.

We can also propose peripheral systems such as automatic flocculant dissolution equipment to match the dehydrator.

We are developing and improving better systems in cooperation with specialized manufacturers.

Aeration equipment

Aeration equipment is the most important machine in a septic tank. Easy handling, robustness, good electrical efficiency, and high agitation capacity are the key factors to select. We use a combined aeration system with a blower and a vertical aerator to perform deep aeration at a depth of 8m, and achieve high electrical efficiency.

-

Blower

This machine is usually used in combination with an aerator in a septic tank. The depth of aeration by itself is about 4m.

-

Horizontal aerator

Floats on the surface of the water and turns its blades like a waterwheel to the air and water, thereby performing aeration and horizontal agitation. It is similar to those used in fish culture ponds, but is designed for sewage treatment. It is easy to handle and inexpensive.

-

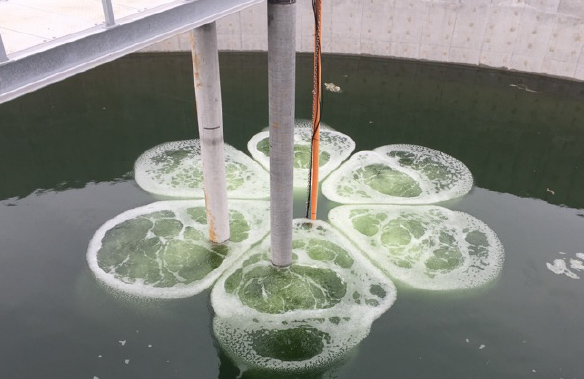

Vertical (underwater) aerators

It is installed at the bottom of the tank and features high aeration efficiency and agitation capacity. 6 air blowers per unit emit fine air that easily dissolves into the water. The depth of aeration by aerator itself is about 5 meters, but when used in combination with a blower, the depth can be up to 8 meters.

Sensor

Bacteria do not tell us anything. It is difficult to grasp their health status and the progress of purification by visual observation. By monitoring scientific information from sensors in septic tanks (like doctors checking electrocardiograms and electroencephalograms in hospitals) it is possible to accurately and easily adjust the operation of aeration equipment and sludge concentration.

-

DO Sensor

(Dissolved Oxygen Analyzer)The concentration of oxygen in the water (dissolved oxygen) is measured to determine the appropriate amount of oxygen to be supplied by aeration.

-

ORP Sensor

The potential of the water (positive or negative) is measured to determine whether it is in an oxidized or reduced state.

-

pH Sensor

Measures the acidity and alkalinity of sludge liquid to determine the degree of ammonia oxidation.

Flocculants and other related chemicals

-

Polymer flocculant BUMO FLOC

Flocculants are necessary to dewater excess sludge and raw water. By mixing and agitating sludge with chemicals, a flocculation reaction occurs, and makes large and hard-to-break chunks with small solids in liquids and substances dissolved in polymer units.

We have a wide range of polymer flocculants, so before using them, we will conduct flocculation tests and select the most suitable product for each site.

We also handle brands designated by the Japan Swine Farm Business Cooperation.

-

Inorganic flocculant

We sell ferric polysulfate and pucks (polyaluminum chloride). It treats Suspended solids and phosphorus that cannot be removed by biological treatment in the lagoon. Inorganic flocculants are a good option in case the treatment conditions deteriorate, especially in places with strict discharge standards.

-

Defoamer

Foaming may occur during the aeration and agitation processes when the treatment conditions are deteriorating. In most cases, the defoamer can reduce foaming. We also handle brands designated by the Japan Swine Farm Business Cooperation.